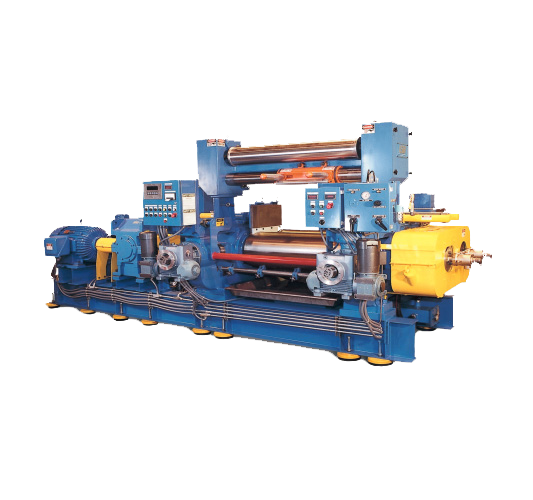

Whether for mixing or sheeting, KOBELCO mills offer a multitude of features that will provide long life and precise material control. Fixed and variable friction ratios permit processing of many different compounds or polymers. Our mills are available in various sizes and can be custom built for your application.

Options include:

- Rolls: Cored/Bored or Drilled

- Bearings: Bronze Sleeve or Antifriction

- Constant or Variable Speed

- Gap Adjustment: Manual, Mechanical, or Hydraulic

- Roll Gap Detectors

- Batch Guides: Fixed, Pneumatic Tilting, or Hydraulic Actuated

- Drives: Mechanical or Hydraulic

- Overhead Blenders

- Mill Knives

See below for detailed information about the Mill frame sizes and capacities:

| Roll Size (Inches) | Batch Size* | Floor Space (feet) |

Self-Contained

Cabinet Units for

Laboratory | 3x3x7

4x4x8

6x6x13

8x8x16

10x10x20

12x12x24

14x14x30 | 1/2

1

2

4

8

18

30 | 4×1

4×3

4×3

4×3

4×3

5×4

7×5

7×6 |

| Direct Drive Units | 16x16x42

20x20x50

20x22x60

22x22x60

22x22x60

26x26x84(1)

26x26x84

26x26x84(1)

26x26x84

28x28x92(1)

30x30x100 | 75

100

125

150

250

250

300

300 | 15×6

17×6

18×6

20×8

26×13

24×9

37×14

28×9

39×14

27×13

31×11 |

| Refiner Cracker | 14x18x24

19x24x36

24x26x42 | | 14×6

19×7

22×9 |

*Approximate, in Pounds of Compound (1.0 S.G.) — (1) Can be funished with 100″ Rolls.

Note: All data provided for reference only and subject to change without notice.